Precision styli for metrology

Procal Solution offers Renishaw make a comprehensive range of precision styli for touch probes. Learn how the quality of styli and accessories play a vital role in industry measurement technology and how Renishaw can support you.

Precision styli are designed to complement Renishaw’s probing systems, to ensure optimum performance. Our standard range comprises over 500 parts, with custom variants available on request. We also have an extensive and experienced applications network that can provide you with full technical support and guidance regarding styli design and their use within your unique application.

Renishaw supplies styli for a variety of applications, including providing compatibility with ZEISS and FARO® probes. To find out more about our styli range for ZEISS and FARO probes, please refer to our precision engineered styli page.

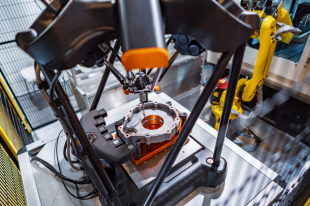

Stylus for CNC, VMC Probe

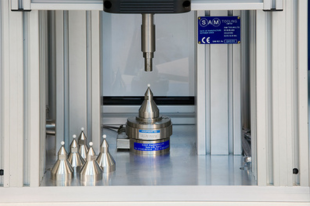

Stylus for CMM (Zeiss, Hexagoan)

Stylus for Equator

Arm Stylus

Custom Stylus

Library

Your solutions partner for automotive manufacturing

Mass production of automotive components relies heavily on repeatable processes of inspections and quality checks during manufacturing.

Although the styli of the inspection probes may seem like a small detail of the process, they are a crucial part of the measurement since they make contact with the component, allowing the probe mechanism to move and the generated signal to allow the measurement to be taken.

At Renishaw we take into account the small details, such as the proper use of the probes. When choosing a stylus, it is essential to consider the features and materials of the component to be measured. Additionally, it is important to consider the probing system in use. Stylus properties such as material, size, rigidity and sphericity can significantly influence measurement performance and system maintenance requirements.

What is a stylus?

A stylus is the part of the measuring system which makes contact with the component, causing the probe’s mechanism to displace. The generated signal enables a measurement to be taken. The stylus is the first link with the work piece. This is why it is vital that the stylus delivers the greatest possible accuracy at the point of contact. The feature to be inspected dictates the type and size of stylus used. In all cases, however, maximum rigidity of the stylus and perfect sphericity of the tip are vital.

The importance of styli for precision

Successful gauging depends very much on the ability of the probe's stylus to access a feature and then maintain accuracy at the point of contact. The performance of your gauging can easily be degraded if you use a stylus with poor ball roundness, poor ball location, bad thread fit or a compromised design that allows excessive bending during measurement. At Renishaw, we have expertise in probe and stylus design to develop a comprehensive range of CMM and machine tool styli to offer you the greatest possible precision.

Top tips for using styli

Use genuine Renishaw styli. Always use styli that are as short and stable as possible. Use the largest ball possible. Are you using components that are thermally stable? Bear in mind the ambient conditions. When putting together styli configurations, refer to the permitted masses as specified by the probe manufacturer. Use the lowest possible number of separate components.